Direct to Film Service

DTF or Direct-to-Film printing is a way to make very high-quality, full-color digital transfers for application to fabrics of all kinds.

The core advantages of our direct to film process include:

Wash fastness – these transfers last like screen printing

Stretch – not only do the transfers stretch along with the fabric, it snaps back into place beautifully

Flexibility of materials – you can apply DTF transfers to any fabric

Very low application time – in most cases, transfer application to a t-shirt is a :15 second heat press

HOT PEEL film - efficient hot peel application versus a slower cold peel method

Local Pick-Up OR Shipping option - if you are in close proximity to our business, we offer a convenient pick-up option for your films. If not, we can ship your films via USPS or UPS.

Direct to Film Inks, Film and Powder

-

RIP Software

If you’re serious about printing, you'll want to connect your DTF printer to software that lets you control and manage your projects. Luckily, our printers come with Print Optimizer RIP software included, giving you full control over your operations.

RIP in printing stands for “Raster Image Processor.” It is a highly specialized driver developed to make the printing process easier, faster, and more accurate. It bypasses all other computer programs to send instructions directly to the printer.

-

Temperature / Humidity Levels

For optimal printing results, it is important to maintain a climate-controlled environment with consistent temperature and humidity based. DTF equipment and materials function best within a moderate temperature range, typically between 68°F and 77°F.

The optimal humidity level is between 40% and 60%. We use water based inks and highly sensitive print heads with thousands of nozzles that have the best quality and performance at optimal temperature/humidity that we maintain.

-

Inks....

A major component of quality Direct to Film images are high quality inks. We use seven different inks in our process…..black, yellow, cyan, light cyan, magenta, light magenta and white. These are pigment-based inks formulated specifically for DTF printing. What it means is that their unique composition is custom-tailored to your machine to deliver vibrant colors and excellent adhesion to the film and substrate.

-

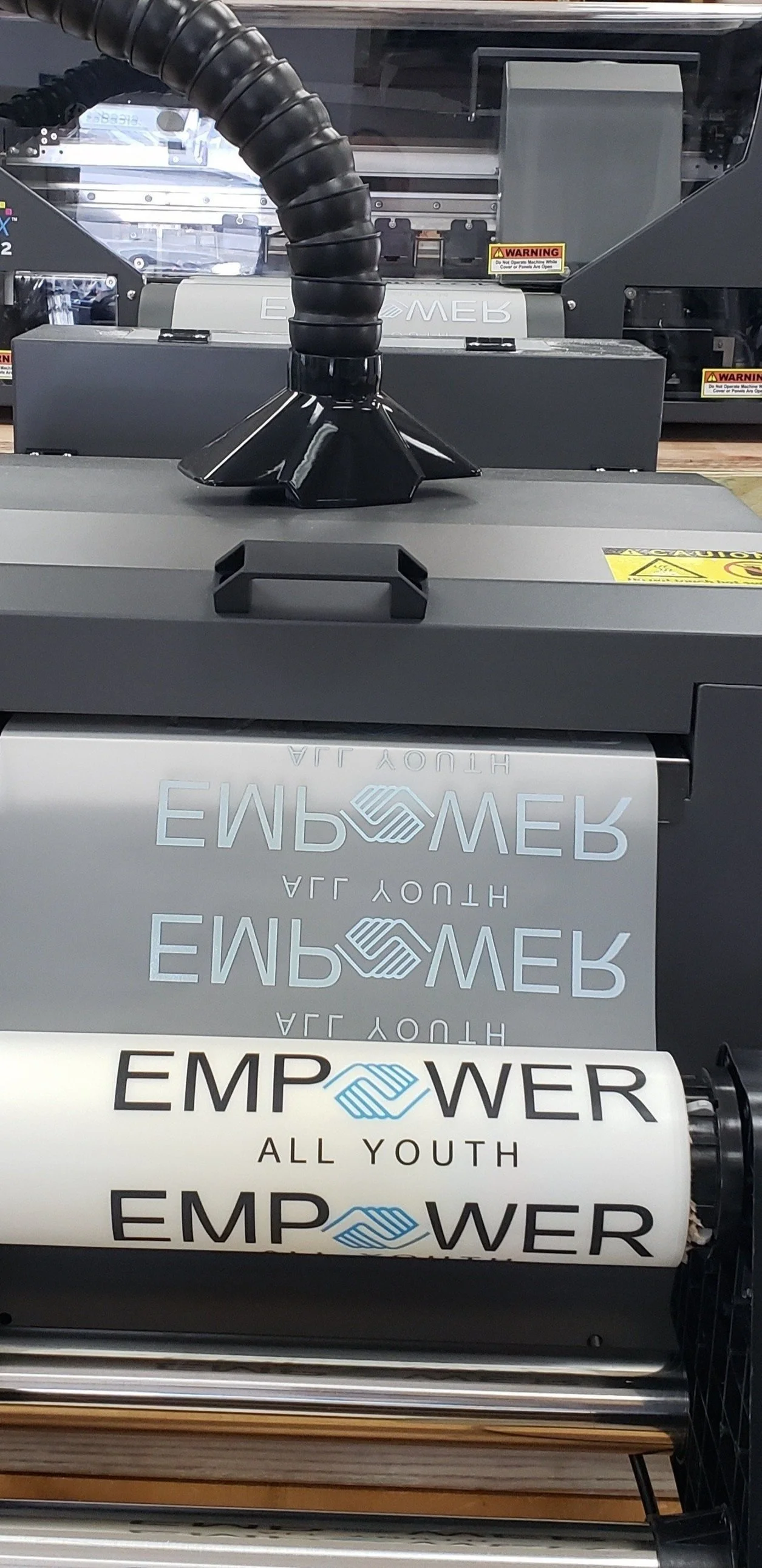

Shaker/Dryer

If you’re powdering your designs by hand, then an automatic DTF powder shaker and dryer machine is the perfect add-on for your printer! It evenly spreads and melts the right amount of adhesive powder directly onto your design.

After the ink is applied, the DTF film will pass through a powder-shaker unit. This unit deposits a type of polyurethane (TPU) hot-melt adhesive powder onto the back of the film (and ink), and to ensure even spreading, it is shaken by a vibrating mechanism.

Finally, the DTF film enters the heating chamber. Here, it heats up the hot-melt glue and finishes curing the inks themselves, so that when it comes out the back it’s ready for use.

-

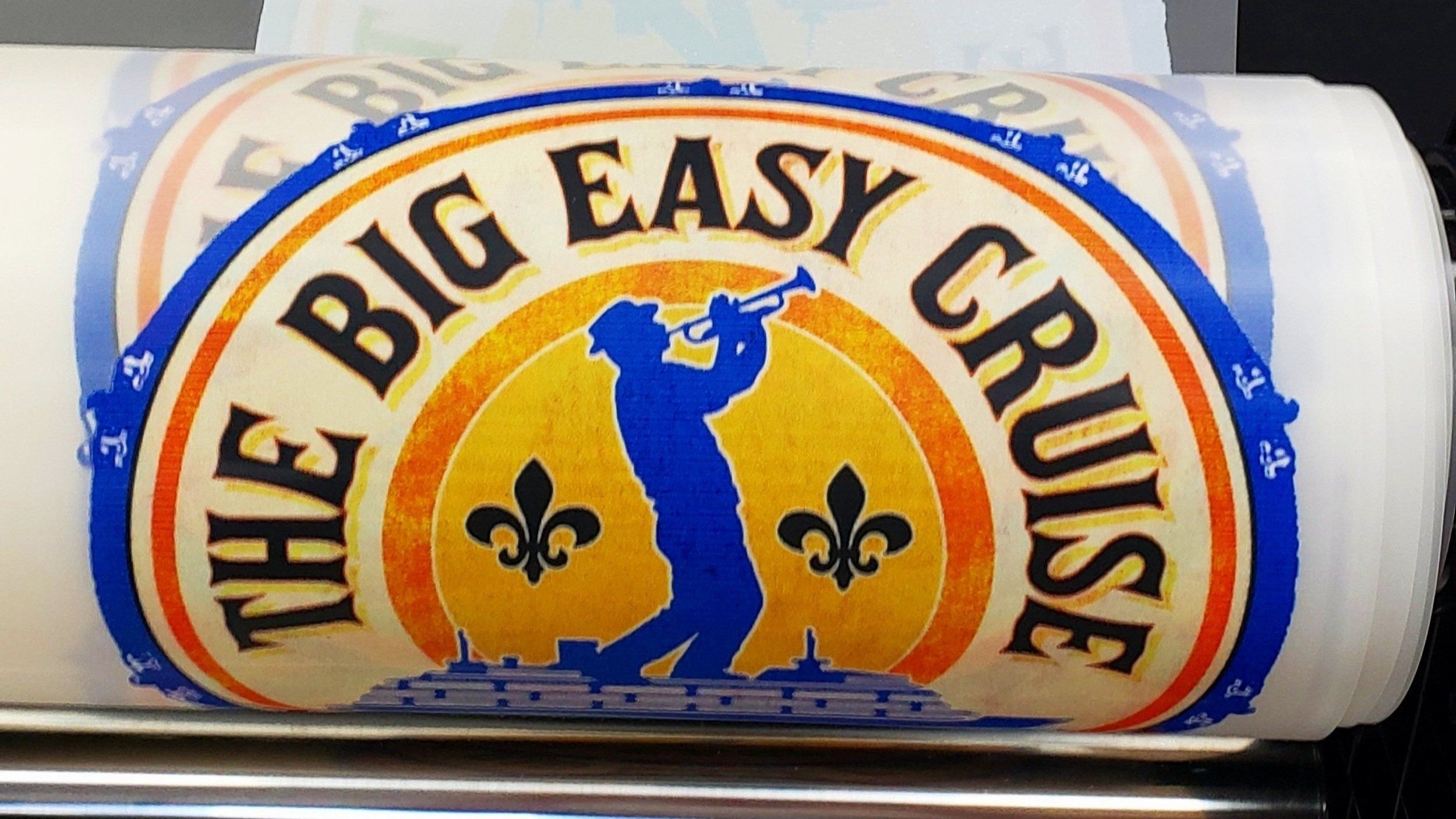

Printed Films....

Your films will be neatly rolled and ready for press. NOTE: We use HOT PEEL film which is the latest technology allowing for a very efficient heat press appliction. The DTF is like a specialized clear plastic film, also known as PET film, or a see-through carrier sheet. Your design gets inkjet-printed on this film so that you can easily heat-press it onto your garment.

-

DTF Powder.....

Right after the printing, a thin layer of this powder is applied to the entire DTF film. This special layer is what makes sure your design bonds with the fabric when you use the heat press.It’s the unique powder adhesive coating that gives DTF prints their signature soft touch. Instead of thick transfer films, or vinyl’s, the Direct to Film Process has only two ingredients. The ink, and a thin coating of powered adhesive.

The soft hand of DTF is holy grail of custom apparel. It’s never been possible to get the incredible soft feel of half-tone screen printing in a transfer process. But with DTF, you get all that and more.

The DTF powder adhesive is moisture-seeking, so it draws itself into the ink of the print and chemically bonds to form a strong permanent adhesive that sticks extremely strong to both cotton and polyester fibers.

-

Heat Transfer....

A heat press is a machine that uses heat and pressure (for a set amount of time) to put a design on a t-shirt or other material. It's an essential piece of equipment for anyone doing custom decorating. This is the final step in the decorating process with DTF’s. Simply applied firm pressure for 10 seconds, immediately peal off the film at a sharp angle (called HOT PEEL) then do a post press for 5 seconds.

Video #1 of our DTF process

Video of our DTF process which includes the CMYK printing, white underbase/highlights printing, powder application, shaker step, curing and rolling of the films.

Video #2 of our DTF process

Maybe you want to turn a apparel hobby into something more or you are looking to expand your printed apparel services. Complete the form below for more details on how we can help you grow your business!

Request pricing and procedures on our DTF Services

Enter your e-mail below to automatically receive full details on our pricing, artwork requirements and heat press instructions.